Tremolo “Hot-Rodding” & “Upgrading”

Something about the OCD nature of guitar players means they commonly need to be tweaking their axes. These tuners or those poteniometers or that strap. Maybe we can all just agree that we want to look cool? HaHa!

And is there anything that looks cooler than pulling off some wicked whammy bar action? No way! So why not make the tremolo look awesome too, right?

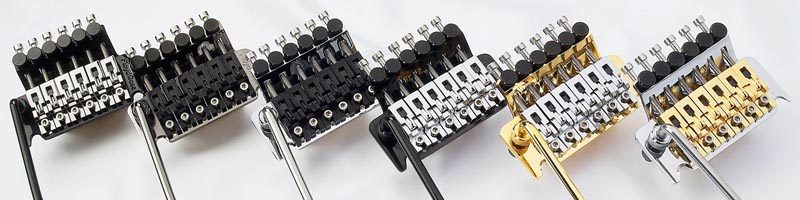

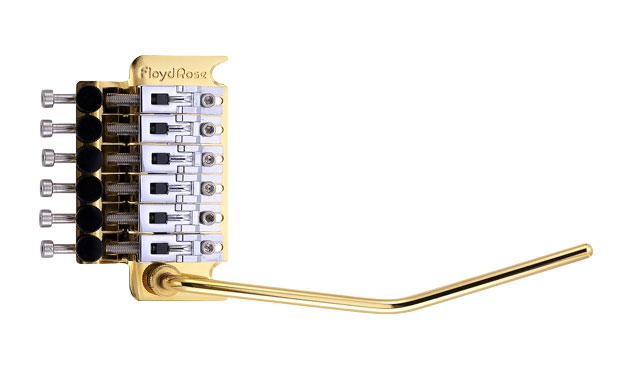

Stainless Steel or Black Alloy

Visual tweaks to the double locking tremolo system started a few years back and appears to have found moderate appeal. One of the more common visual alterations comes in the form of stainless steel screws. That includes saddle mounting screws, string lock screws, and nut clamp screws.

Of course, stainless steel is more resistant to corrosion than the standard black alloy steel screws. If you’re like Angus Young and sweat a lot on stage, that could be a more practical option. So then, what about where the rubber meets the road? Or rather, where the metal meets the metal?

Let’s get this out of the way first. I’m going to cover this in tensile strength. That is the maximum load in tension (pulling apart) which a material can withstand before breaking or fracturing. Other mechanical properties include Yield Strength and Proof Load. Yield Strength is the maximum load at which a material exhibits a specific permanent deformation. Proof Load is an axial tensile load which the product must withstand without evidence of any permanent set. So yeah, let’s keep it simple.

Your common black alloy screw found on the Original Series Floyd Rose tremolo is generally Class 10.9. That’s a tensile strength of about 145-150 KPI (as in, thousands of pounds per square inch). You can hit up a place like Fastenal or your local bolt and screw supply and find Class 12.9 black allow, which has a tensile strength of about 176 KSI. For reference, that about as strong as some (but not all!) of the titanium options out there.

Some of the very strongest stainless steel for this purpose is the A4 grade, which can have a tensile strength of about 116 KSI. So even the low-end Class 8.8 black alloy is stronger. Yet your more common stainless steel bolts are 18-8, having a minimum tensile strength of 65 KSI. Approximately 55% less tensile strength than the Class 10.9! Wow!

The Reader’s Digest version is that black alloy screws are going to be stronger than stainless steel screws. But what about the “stainless” part? Come on. I have Floyd-loaded guitars over 30 years old with no issues on the stock black alloy parts. Take care of what you have and it’ll last just fine while being easier on your wallet.

Additionally, Floyd Rose is honest in describing stainless steel as “highly resistant to corrosion” and leaving it at that. Other outlets for these stainless steel screws might appear a bit disingenuous with the suggestion of stainless steel being harder. Pfft! Those pesky facts! HaHa!

Floyd Rose is also much more fair in the pricing of the stainless steel parts. Consider $5.10 for a set of 6 saddle mounting screws. You can find copycat Floyd mom-and-pop type places charging about 4x more than Floyd Rose. That’s over $3 each! The top of the line A4 grade stainless steel from Fastenal is $0.0992 each. I don’t know about you, but if I’m going to take the stainless steel path and don’t want to deal with tracking them down at the hardware store, I’d rather pay Floyd $.85 each than some other place more than $3 a pop. If for nothing more than Floyd being honest in their description.

Brass or Black Alloy

Speaking of tensile strength of metal. By comparison, the “bell brass” that many places claim to use for sustain blocks is about half of that at approximately 58 KSI. “Naval brass” is around 25 KSI. While not having a sample of the “naval brass” product, I cannot attest to the durability. Although it might appear that the numbers speak for themselves: 100+ KSI or about 25 KSI.

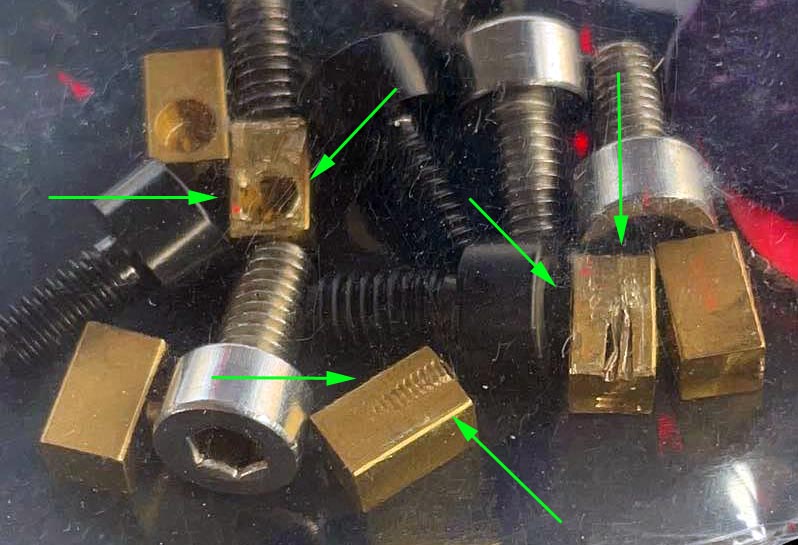

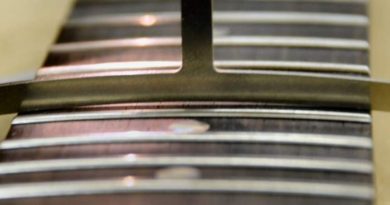

More recently, someone sent me a photo of some “naval brass” lock insert blocks. Check it out:

Holy crap (literally!), Batman! Not just string indentions and deformations, but that one is beyond crushed. It almost looks like delamination, but most likely simply cracks. And yet that product is literally described as “…will not expand or crack…”! Sure about that? LOL!

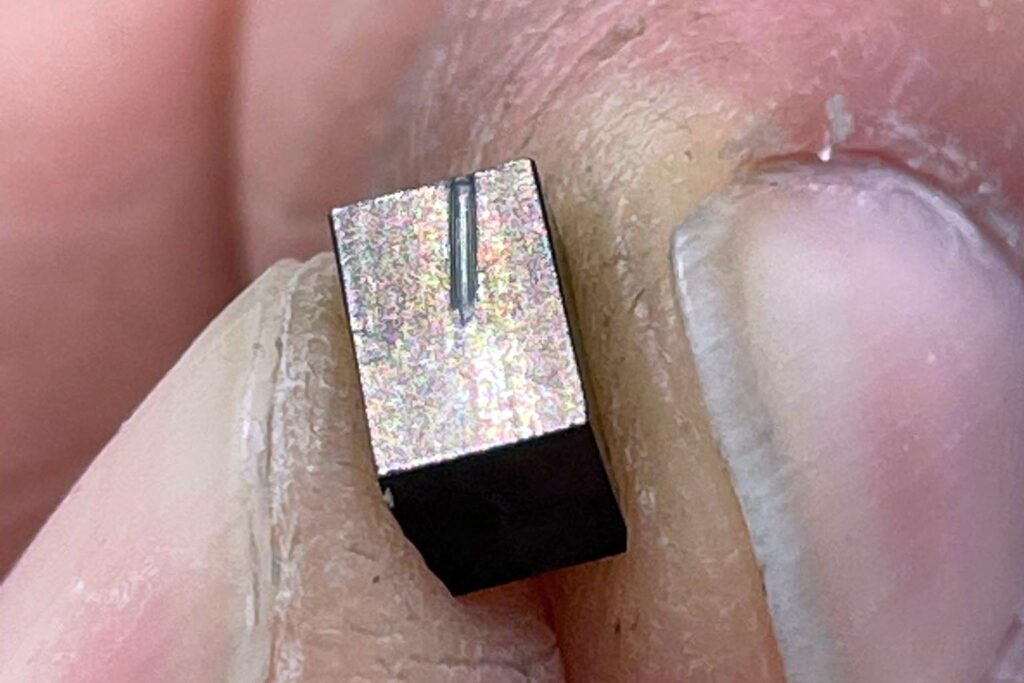

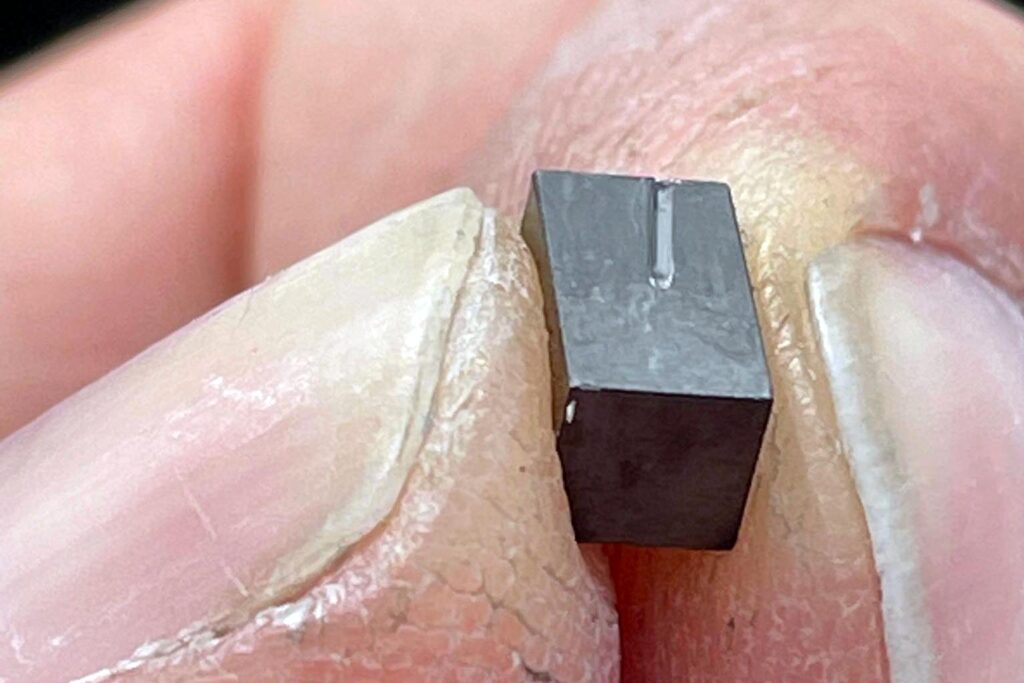

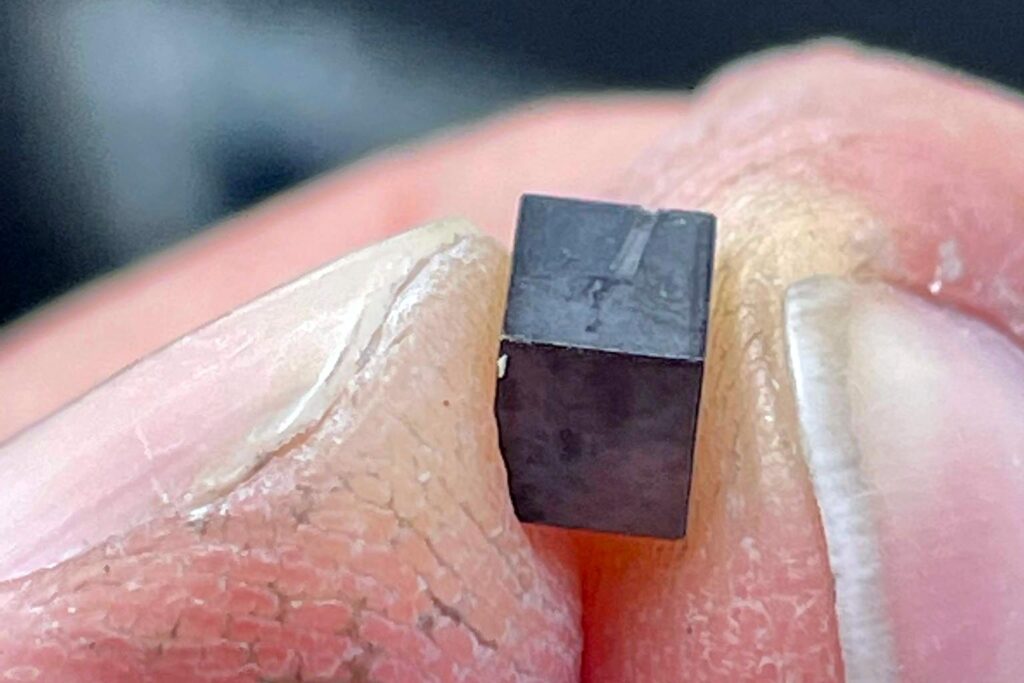

Speaking of style over substance, these photos are also sent to me. It is my understanding this is from the same source as those “naval brass” inserts. These are the titanium inserts that are available in different colors. In this instance, black:

The sender is saying that is after a single use! Sheesh! After showing those to an expert in the field, the suggestion is it’s an indication of not getting proper heat-treating.

Seems like there are definitely things to consider. At the end of the day, some stainless steel screws are used in certain automotive industry applications to attach panels and so on – probably a good idea for cars near the coasts. So I’m not saying that stainless steel screws are bad. When it comes to your locking tremolo applications, it will depend on your goals… and how much torque you apply to these screws.

We could get into other things, like noiseless springs and heavy duty springs and brass tremolo claws (which include the brass screws!) and how the official Floyd Rose parts are also more cost effective that some of the alternatives… but I know you guys are smart (you’re reading this, aren’t you? LOL!).

As consumers, maybe there are a few valuable insights mentioned here to help make the best use of your hard-earned dollar. Personally, my approach is to stick with the real-deal authentic genuine official Floyd Rose parts.

Floyd Rose Website | Facebook | Twitter | YouTube

7 string 16Ω 59 Airbucker Alnico 2 Alnico 3 Alnico 4 Alnico 5 Alnico 8 Bare Knuckle BKP Brown Sound Celestion Ceramic Custom Shop Dean DiMarzio DMT Dual Resonance EVH Fishman Floyd Rose Fluence Gibson Humbucker Ibanez JB Jimmy Page John Petrucci MJ Mojotone P90 PAF Pariah Pickup Satch Satriani Schaller Seymour Duncan Singlecoil Single Width Speaker Steve Vai Tech Tip Virtual Vintage