Warmoth Custom Build

Warmoth provides best-in-class replacement parts and custom parts in the guitar industry. The WA-based craftsmen and artisans are behind bodies and necks for guitar shops large and small.

Sure, I can take raw lumber and knock out a guitar body that I’ve been told will best a luthier. But I’m not a fan of making necks. Applying the radius. Installing frets. A walk in the park. It’s the blasted neck profile. One slip up and all that work is good for the trash heap. LOL! It is with such an experience that has me looking to a completed neck.

Being as about as patient as anyone else (HaHa!), Warmoth’s In-Stock Showcase is a great starting place. The parts are practically ready to go, minus a few custom preferences. For necks, you choose the frets, the nut, and the size of tuning holes. For the bodies, the options are commonly the pickup cavities and the bridge options.

The Neck

This is an opportunity to stretch out the palette a bit. I’m seeing some 25-1/2″ scale roasted maple necks that are of great interest. I’m liking the roasted maple, as there is no real need to seal up for finish the wood. Being able to see the actual neck on the website gives the luxury of paring it down. When it comes to necks, that is pretty much going to be how the wood grain tickles the eyeballs.

Owning my share of Fender, Charvel, and Jackson guitars, I have the standard “Strat” head shape pretty well covered. The vibe of the “Warhead” shape looks like fun, so I’m going with that. There is a need to plan out ahead well enough to know what tuning machines will be at work. In this build, I go with Gotoh. Other options are 6150 stainless steel fret wire, a nut shelf for a Floyd Rose R3 nut, and the “standard thin” neck profile.

The “standard thin” is advertised as similar to a modern Fender American Standard Strat profile. I have a 1990 American Standard Strat. I do consider it to have a little more meat than the Warmoth “standard thin”. Not a bad thing. Just different. The “fatback” and especially the “boatneck” hit me with great interest. I think the “59 roundback” is calling to me for the next Warmoth project. But, one thing at a time. LOL!

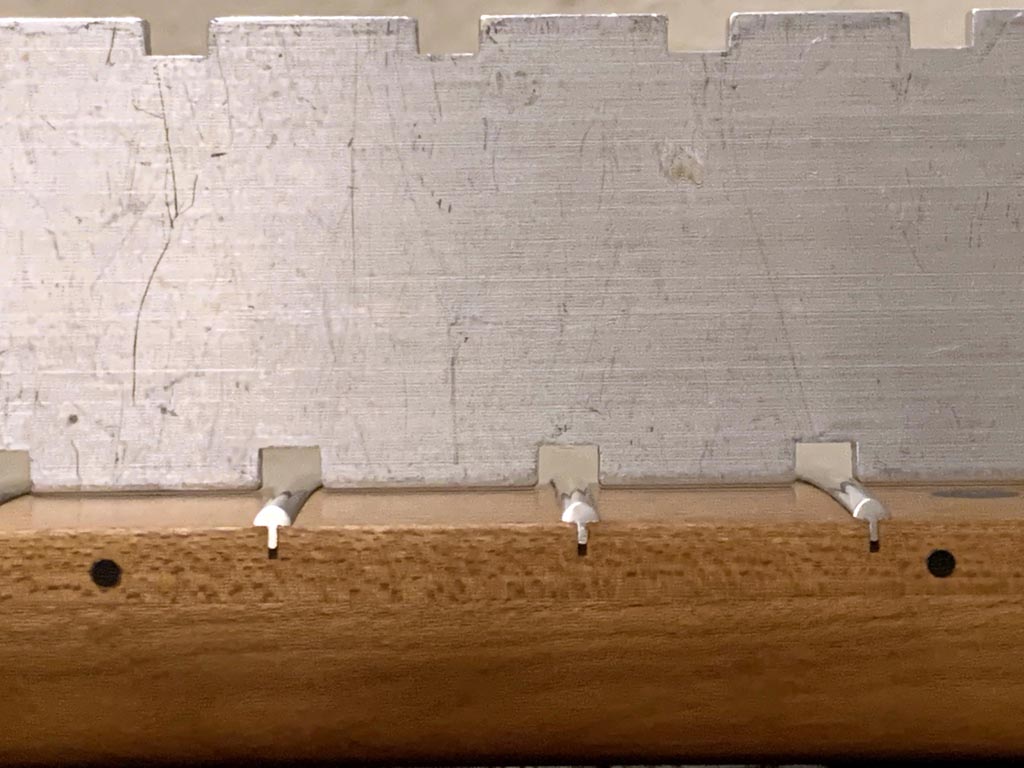

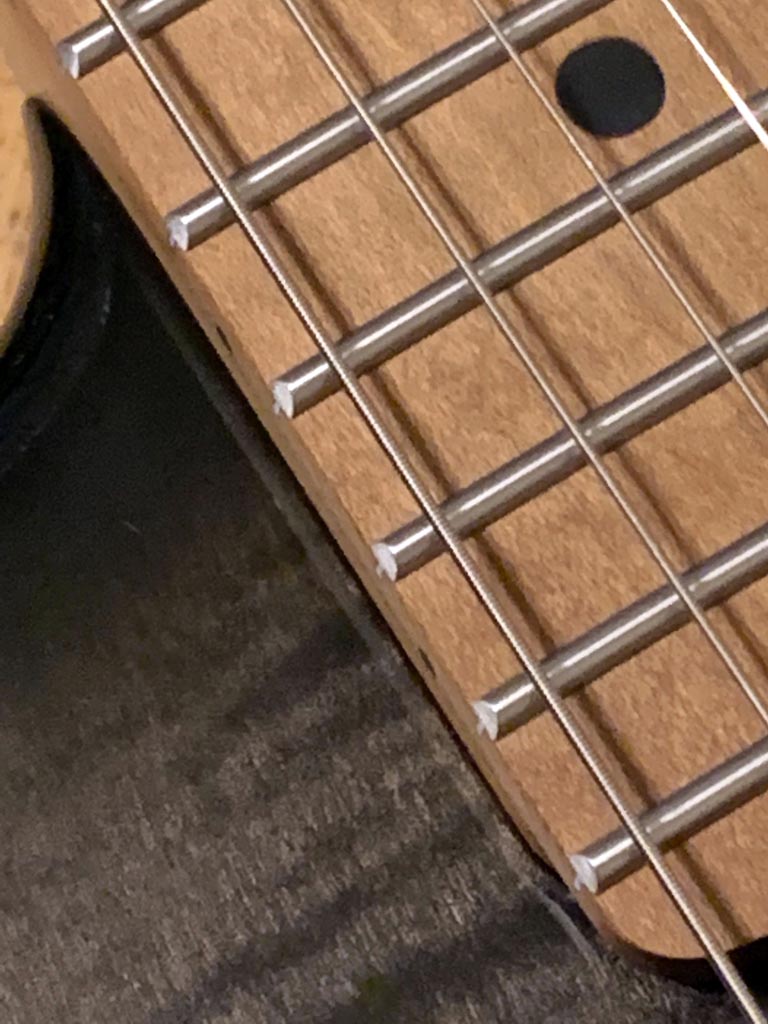

Out of the box, the neck is as straight as you’d want it to be:

The Body

There is a real opportunity for fun with the body selection. I’m staying on the general approach to a “Super Strat”. So the “Stratocaster” and the “Soloist” style bodies are what I’m looking at in the Showcase. Already having plenty of alder and maple bodies, I want to break it up a little. Brighter woods are where I want to go this time, so I start to look for some ash. There are several to consider, and my own personal preference narrow it down to a pair of “Strat” styles. Both are dyed finishes, which is fine.

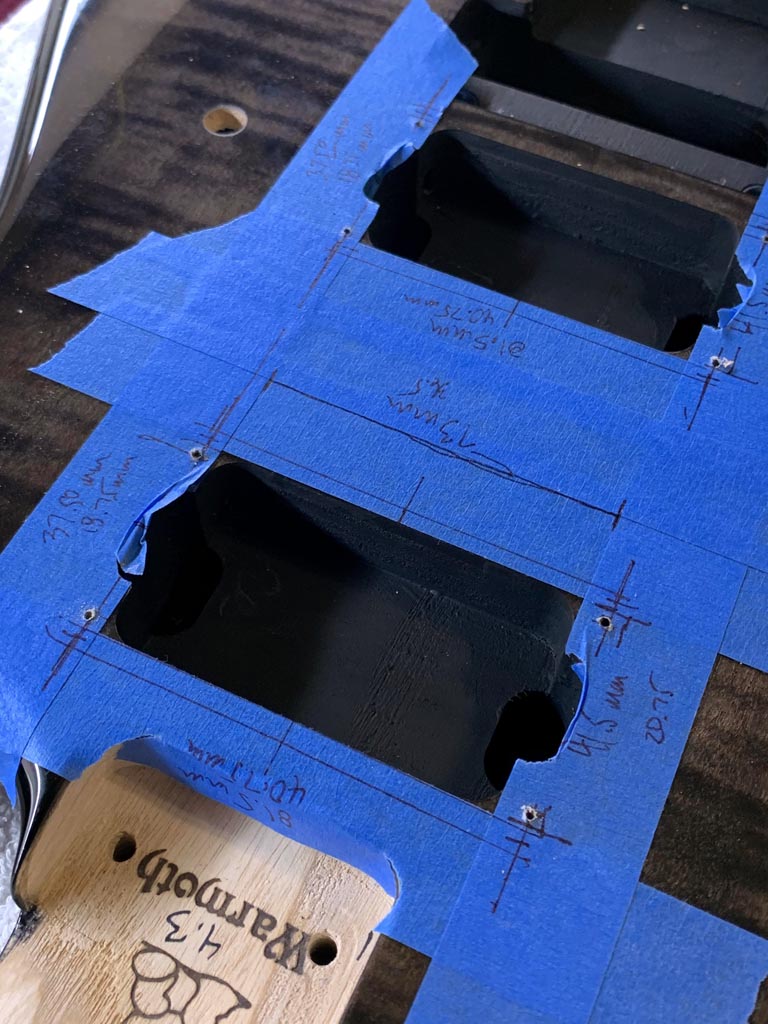

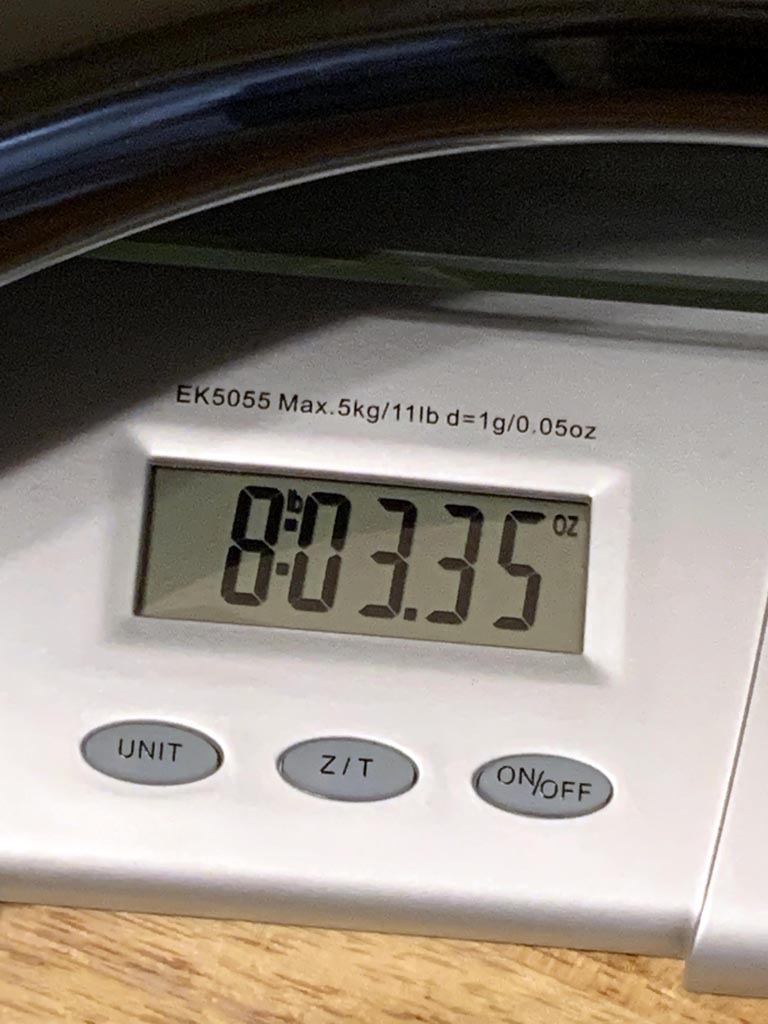

The winner is a swamp ash body with a flamed maple top. It has a black dye finish with a gloss clear. The options that I can select to complete the body is a recessed rout for the Floyd Rose, a hum-hum pickup config, and a 3/4″ (19mm) side jack hole. It hit the scale at 3 lbs, 15.75 oz. Alright then, 4 lbs. LOL!

This body comes as-is with a “Strat shape” neck pocket, standard 4-bolt mounting holes, forearm contour, and tummy cut. Of interest on this one is the contoured heel, which actually has no relevance to my final choice. I do see where some people have issue with how the heads of the mounting screws rest in relation to the angle of the heel contour. As OCD as guitar players can be, I am finding no issue with it at all and my opinion would be that the complaints are of no concern.

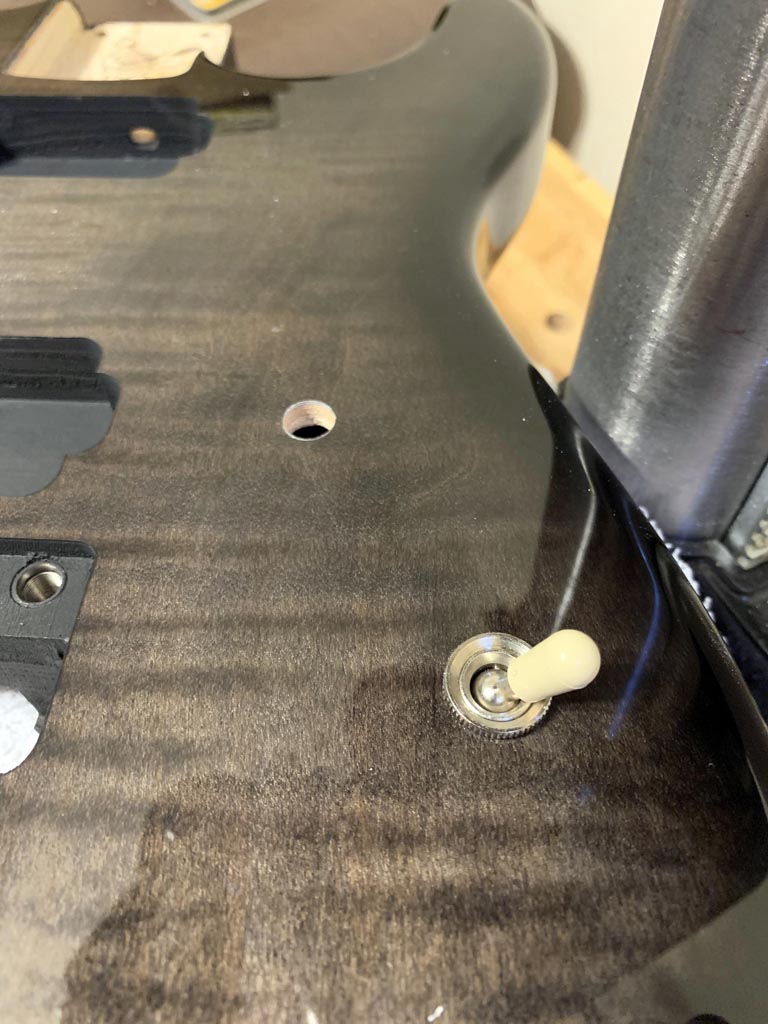

If you think you are noticing the lack of holes for controls, you are right! LOL! I want something that pretty much mirrors the placement of the Charvel single-volume and single-toggle configuration. So I am drilling those myself with the drill press. The drill press is also my preferred technique to press in the Floyd Rose inserts for install.

The Hardware

To round out the project, I pretty much know the must-have hardware. It will require the bridge, nut, tuners, and strap buttons.

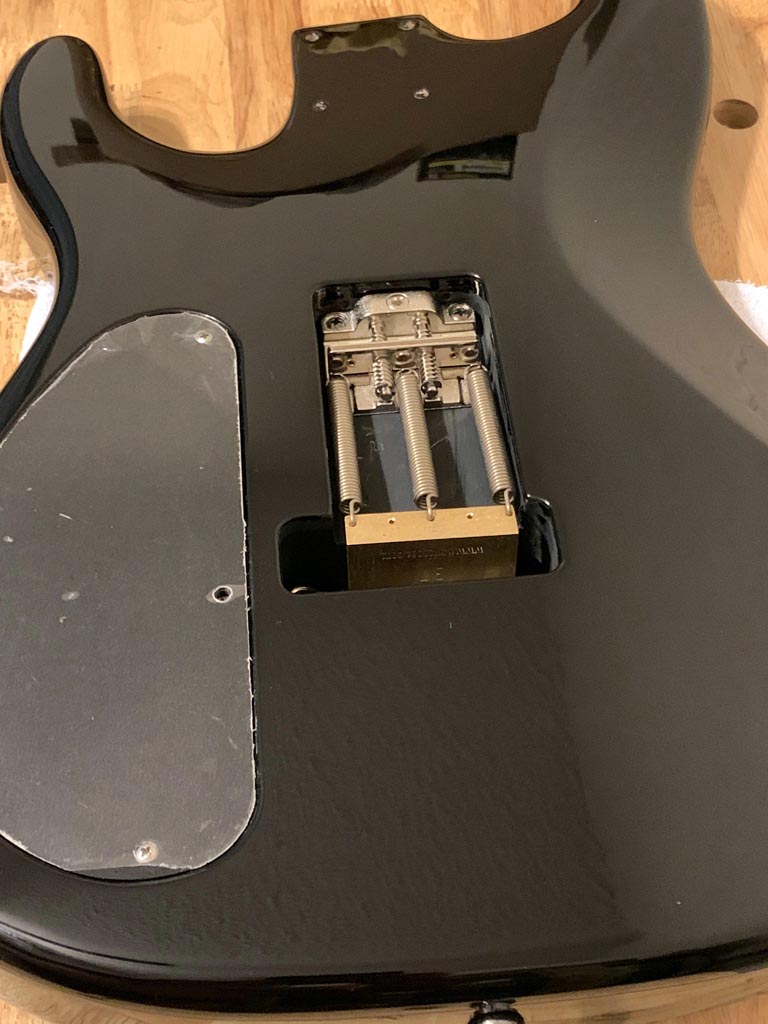

There is really no choice for my guitars outside of genuine Floyd Rose tremolo systems. And of those options, I know the 1984 model will yield the results that I want from this project. The one variable is that I install the mounting studs and inserts rather than the mounting wood screws. Just a preference.

The Floyd Rose locking nut install is a thing of beauty. For starters, the neck-thru old-style original install method makes it simple. From the back side, there is the slightest bit of room to cheat to the left and right. This allows for the perfect alignment of the locking nut on the nut shelf. And the best part, the nut shelf is cut for practically perfect string clearance. My trusty Nut Slotting Gauge is literally smiling during the setup.

Another step off the beaten path is the trem spring claw. I’m going with the Schaller Sure Claw in the tremolo cavity. It’s just as easy to install as a traditional claw. I find it to add more mass and stability to the kinetic chain. It also makes setup and maintenance quicker and easier.

Check out the clear gloss on that finish! You can also thank Lizard Spit Guitar Polish for helping you see more of the finish and less of my fingerprints! HaHa!

From there, it’s an up close and personal relationship with a straight edge. HaHa! First to align the backside of the tuners. And then to set up the install of the pickup mounting rings. When it comes to the best alignment of the rings in relation to the pickup cavities and in relation to each other, I think corporate tax records might use less math. LOL!

This project also gets the Schaller S-Locks strap pins. Measure the positions and pre-drill. The design of these pins makes install a breeze and results in no wiggle. And they retain the classic Schaller locking pin dimensions. So this works with any of my other straps that have the older classic locking mechanism.

I’m going with a standard “football” style jack plate here. The Pure Tone Technologies Multi-Contact 1/4″ output jack. This is the 2nd guitar in the herd with this jack and I’ll be talking more about Pure Tone very soon. I do pre-wire the connections before install. For good measure, a bit of heat shrink goes over the solder joints.

Major Assembly

The neck mount is as easy as putting Tab A in to Slot B. It’s like buttah! HaHa! Not so tight so as to be forcing anything, but in no way loose. This is a big moment-of-truth sort of thing. And thankfully, Warmoth clearly knows how to make parts that go together properly. In fact, essentially perfect.

A thing to consider with a contoured neck heel is how the screws play in to the install. Different lengths of screws are a must-have, lest something pokes through the fingerboard. Warmoth sells a set of these screws, so the math lesson stops at the pickup ring alignment. HaHa! Once again, the neck plate and the mounting screws do not operate on a 90° angle. There is the slightest bit of the screw’s edge that breaks that plane. But I find it in no way to be noticeable, other than visually on the most anal-retentive level. In other words, it’s totally fine.

Electronics

The preferences in my wiring harness remains Bourns 500k pots and Switchcraft 12120X 3-way toggles. The pot is a push-pull for series-parallel operation on the neck humbucker.

In the time that this Warmoth guitar has been functional, many different pickups have been in play. It has actually been a fun learning experience to find the voice of which pickups that work with the wood selection. Here is a possible theory. The parts of the neck and body without a finish.

This neck has no finish whatsoever. The pickup and Floyd Rose recess routs are also bare wood. The pup cavities and entire trem cavity (top and bottom) gets a covering of conductive shielding paint. Yet the areas lack a complete “sealing”. Clearly not scientific, but I will continue to consider the possible tonal influence.

Overview

This type project is something I hope to be doing again. And Warmoth makes it easy. The precision-made parts go together easily and accurately. No need to shim this or cheat that. The body is comfortable and the neck has a familiar feel.

Warmoth’s In-Stock Showcase is a winner as an option to get finished parts within a week or so. Otherwise, it might be a month or longer, depending on the options. Let me put it this way. The black dye finish is not my first choice. But it was ready to go and it gets a lot of positive feedback.

The Phineas ‘Bowman’ Model

The final result is a guitar I can be proud of and cost much less than the same specs from most guitar companies. Added to that, the body and neck are Made In America. Give Warmoth a look for your next project.

And since I know you will be asking, the final weigh in for the complete project is 8 lbs, 3.35 oz.

Warmoth Website | Facebook | Twitter | YouTube | Instagram

Floyd Rose Website | Facebook | Twitter | YouTube | Instagram

Pure Tone Technologies Website | Facebook

Schaller Website

Lizard Spit Website | Facebook | Twitter | YouTube | Instagram

7 string 16Ω 59 Airbucker Alnico 2 Alnico 4 Alnico 5 Alnico 8 Bare Knuckle BKP Boot Camp Brown Sound Celestion Ceramic Custom Shop David Shepherd DiMarzio Dual Resonance EVH Fishman Floyd Rose Fluence Gibson HSP90 Humbucker Ibanez JB Jimmy Page John Petrucci Les Paul MJ Mojotone P90 PAF Pariah Pickup Satch Seymour Duncan Singlecoil Single Width Speaker Steve Vai Tech Tip Tremolo Virtual Vintage